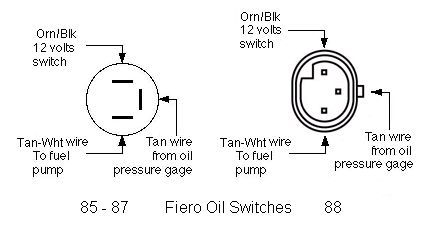

Most current production oil pressure failure switches are provided with terminals for the connection to a crankcase heater. Oil pressure safety control with an approved switch is a condition of warranty.

Electrical Symbols For Other Pilot Devices

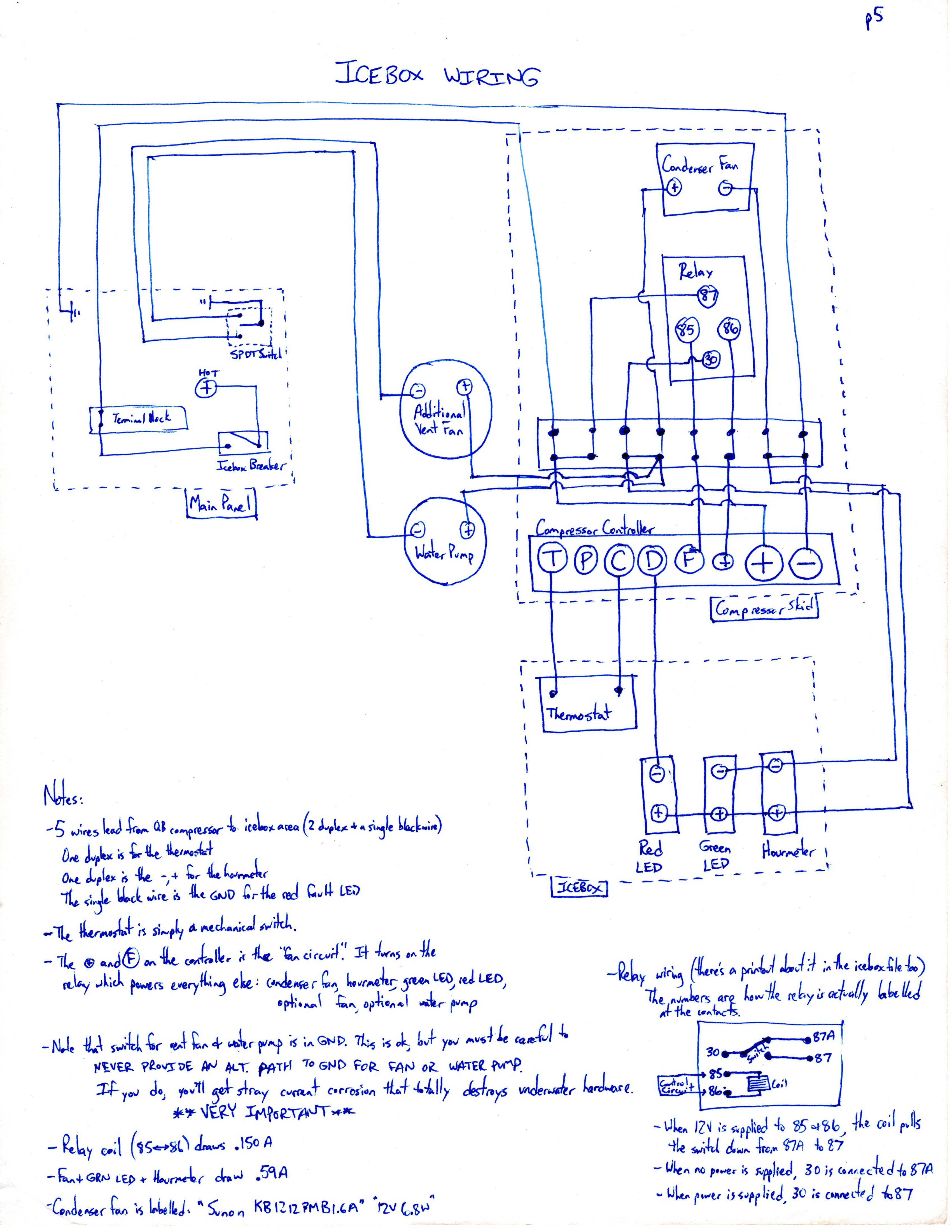

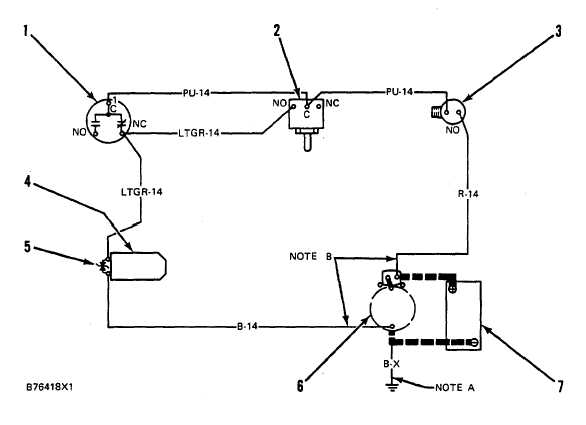

Refrigeration oil pressure switch wiring diagram. For external wiring diagrams. Here are the instructions on how to wire an oil pressure gauge. Net oil pressure can be read by connecting two pressure gauges and comparing the readings one should be connected to the oil pump and the. The factory set pressure adjustment provides. Since the terminal arrangements vary reference should be made to the wiring diagram provided with the switch. Series p28 oil pressure cutout differential pressure control with built in time delay relay application the p28 controls provide dependable and economical oil pressure cutout for pressure lubricated refrigeration compressors.

To wire an oil pressure gauge make sure to get a copy of the wiring diagram for the specific brand and model of the devicethe manual usually comes with the purchase but the manual can also be downloaded from the manufacturers website. Each part ought to be set and linked to other parts in specific way. Oil pressure switch wiring diagram will definitely help you in increasing the efficiency of your work. If not the arrangement will not function as it ought to be. Oil pressure differential normal oil pressure is between 105 and 42 bar higher than crankcase pressure. Oil pressure switch wiring diagram alco oil pressure switch wiring diagram danfoss oil pressure switch wiring diagram engine oil pressure switch wiring diagram every electrical arrangement is made up of various distinct parts.

Specifications for typical wiring diagram.