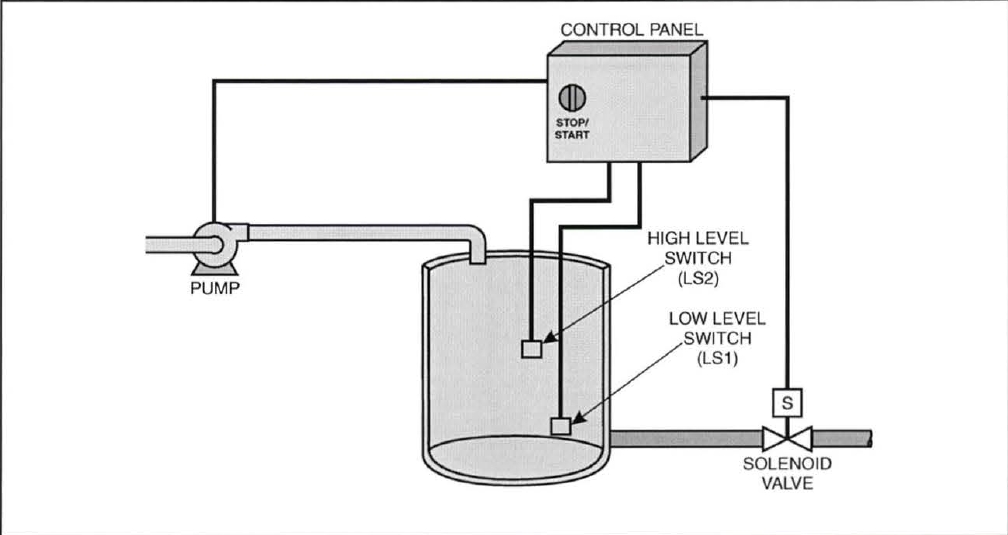

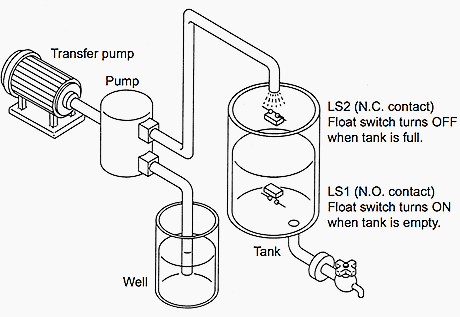

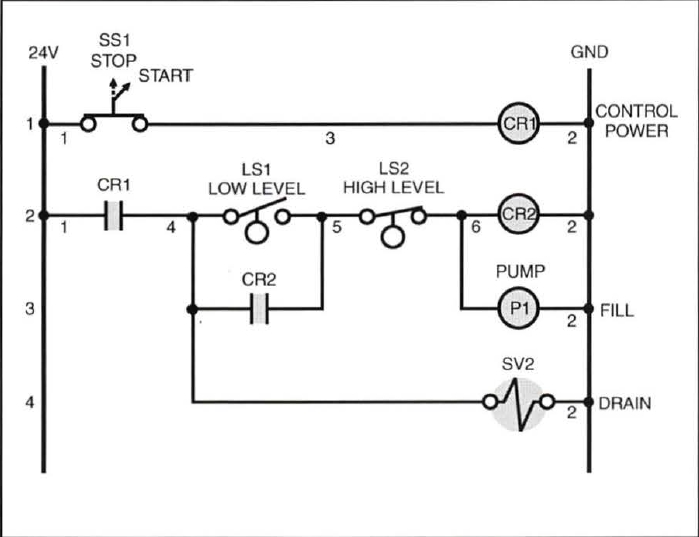

Description and installation duration. The liquid rises until the top float switch closes and energises the relay.

Lessons In Electric Circuits Volume Iv Digital Chapter 6

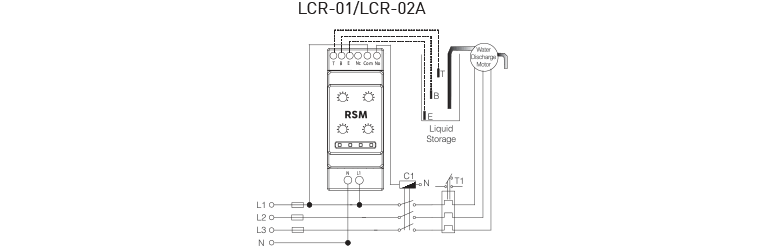

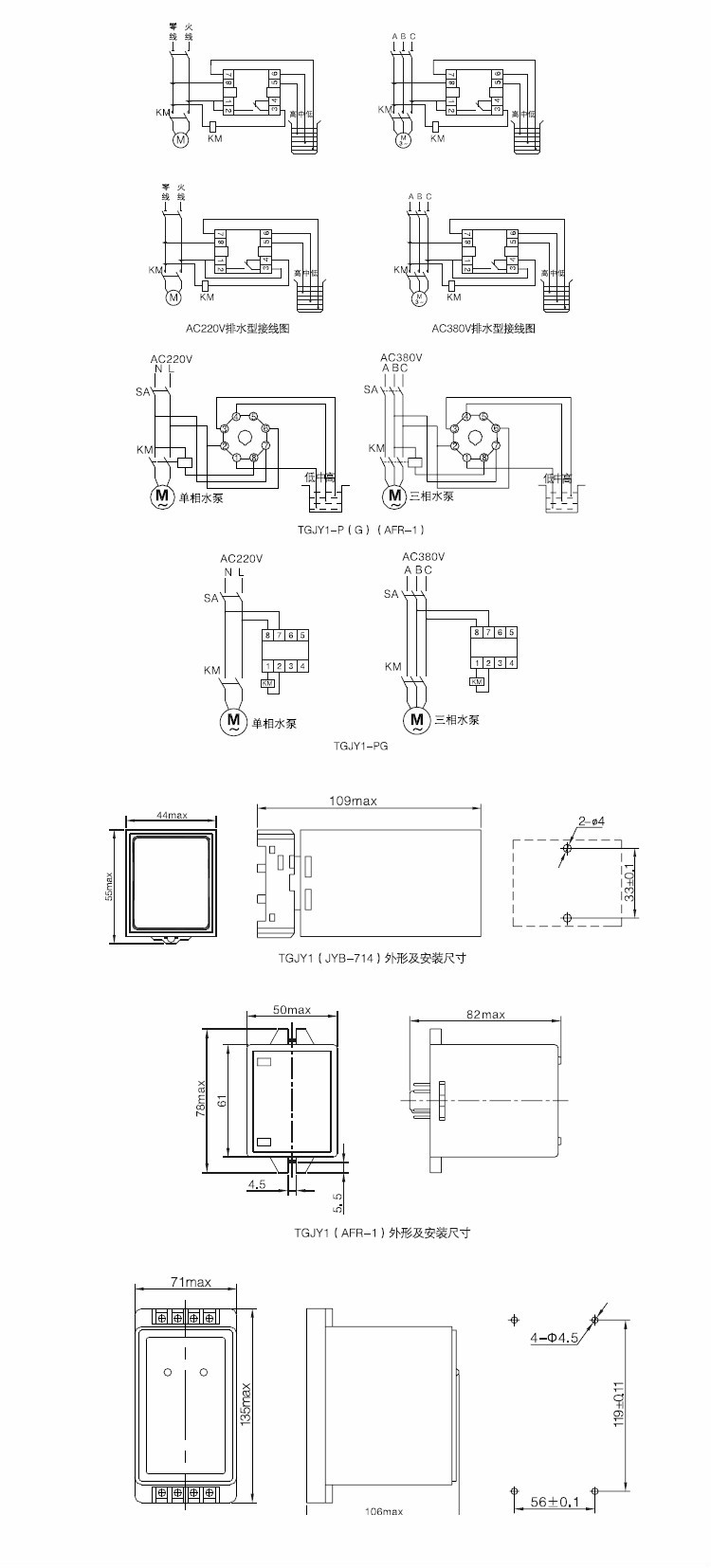

Liquid level control relay wiring diagram. Ladder diagram basics 3 2 wire 3 wire motor control circuit duration. Be sure to check if the controls have time delays and be. The relay remains energized until the liquid level rises and touches the high level probe. Check wiring between probes and relay for correctness and continuity. The illustration to the right graphically defines the typical warrick liquid level control system which includes three basic elements. 1500 induction control relays 1500 series installation service manual principle of operation a bw fl oatless liquid level control system consists of a relay of the proper type a holder designed to support one or more electrodes or probes in the liquid container and the corrosion resistant electrodes themselves.

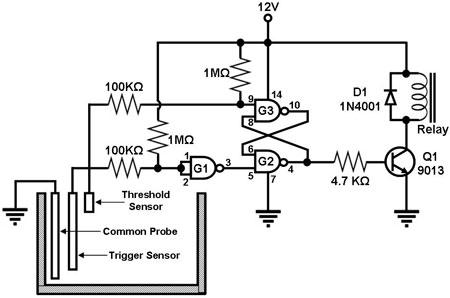

Since bw level control systems use the liquid as an electrical conductor to complete the relays secondary circuit and since the resistance or the liquids varies it is necessary that each induction relay be equipped with a secondary coil that will operate over the resistance of the liquid it controls. Wire the control devices to the series 17 relay as shown in the specific application wiring diagram on the inside pageswarrick troubleshooting guide. In as much as all bw induction. Fluid level control schematic diagrams with lm1830. When the liquid level falls below the low level probe a 1 second time delay begins and the led flashes redat the end of the time delay the output relay energizes and the led is red on. Pete vree 331408 views.

In response to liquid levels sensed. In a typical application where the device is employed for sensing low water levels in a tank a simple steel. The control is an electrical device with contacts that open and close. Sewage and waste water level detection. Liquid level control relay. This diagram is for the circuit to empty a tank using two normally open float switches and a two pole changeover relay.

This circuit uses two level switches to maintain the level within a given range. Electromechanical relay control systems were one of the first types of control systems used in the process control industry to perform onoff control. Failure of relay to change state when liquid touches probes. The pump is on to fill the tank. This is a typical relay based control system that is used to control liquid level in the tank. Here is a simple level switch circuit that switches on one relay and switches off another relay when the fluid level exceeds the set limitthis circuit is a modification of the simple water level indicator previously postedwhen the water level touches the probes positive supply is connected to the base of q1 through fluidthis makes transistor.

One set of relay contacts connects the pump to the supply and the other maintains the relay on state while the level. The bottom switch will be closed provided the liquid is above that switch point. The lm1830 fluid level detector circuit is a device intended to signal the presence or absence of aqueous solutions featuring low external parts count wide supply operating range internally regulated supply and ac or dc output.

.jpg)