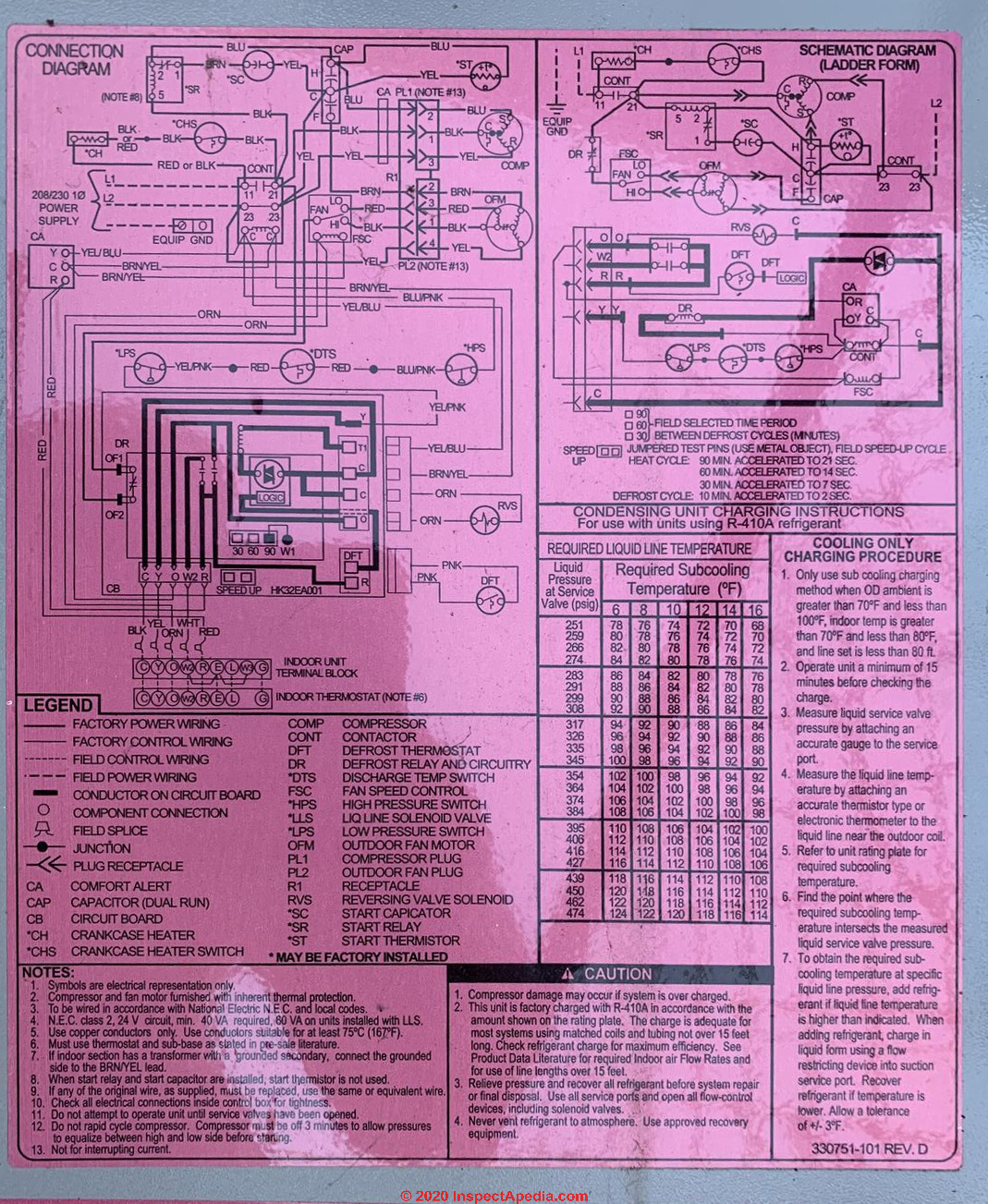

Power module life estimator. Route other temperature switch wire.

Condenser Unit Fan Stopped Running Diagnosis Amp Repair For

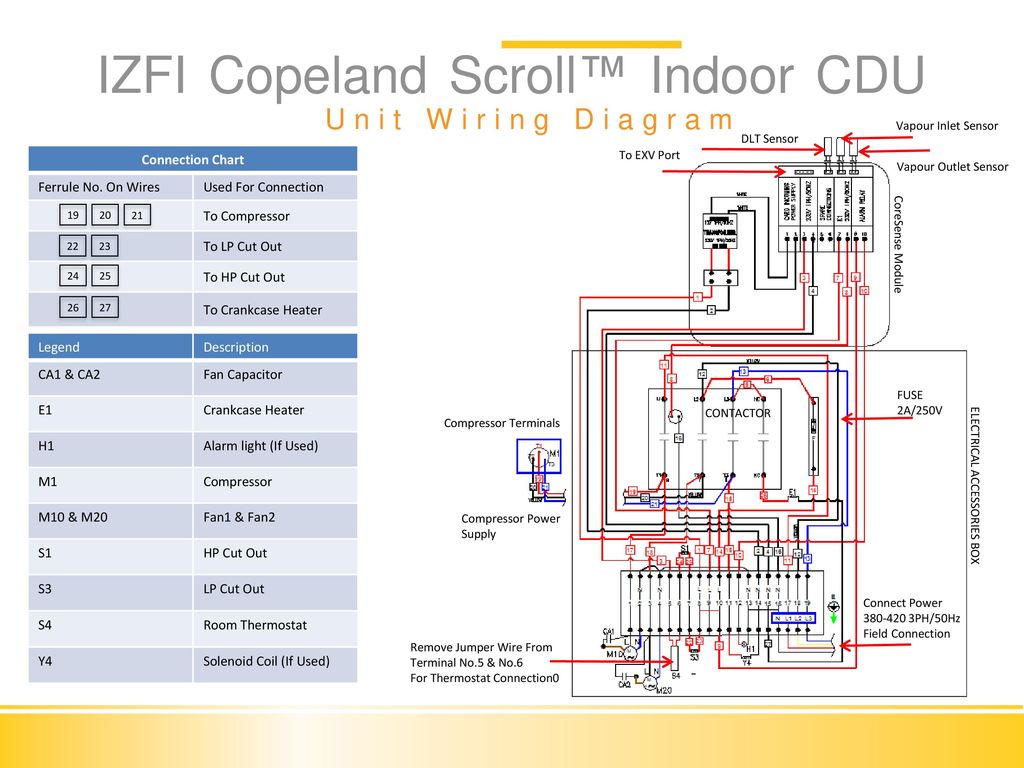

Copeland crankcase heater wiring diagram. Tecumseh to copeland brand 9 general notes 13 compressor data notes rating points 14 zb zf and zs models 15 zr models 27 zfh models 59 zp models 61 zrtzz tandem models 62 electrical diagrams 65 standard compressor drawings 66 electrical components 79 bill of material description 82 accessories 84 miscellaneous information crankcase heaters 87. Would you say crankcase heater is wired correctly being powered all the time. Crankcase heater filter by press enter to collapse or expand the menu. Route other switch wire into control box. Found this unit wired so heater is only energized with compressor. 1 printed in the usa.

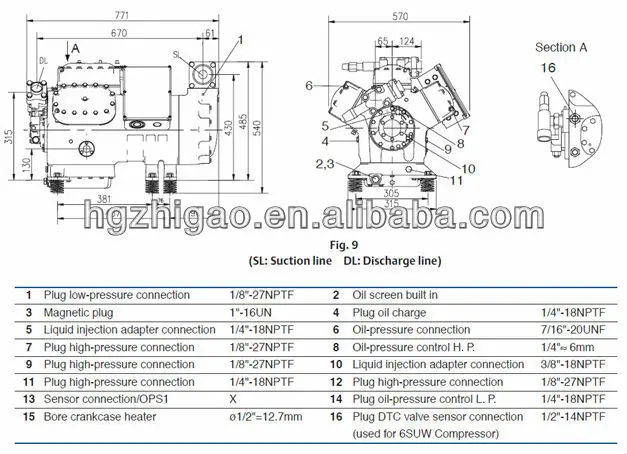

Fasten heater firmly in place with clip provided on heater. A crankcase heater is used to prevent refrigerant migrating into the shell during standstill periods. 1 1 of 1. The crankcase heater should immediately begin to heat. The crankcase heater will heat at all times. Copeland 4mtls are only applicable for transcritical co 2 r 744 applications see table 3 for list of available models.

Fasten heater firmly in place with clip provided on heater. Liquid analysis wiring diagram. Copeland 4msls are only applicable for subcritical co 2 r 744 applications see table 4 for list of available models. Oil charge and recharge values are. Route one crankcase heater wire into control box and attach to quickconnect line voltage terminal 11 on contactor. 737371 take a look at this schematic.

Wiring route one crankcase heater wire into control box and attach to quick connect line voltage terminal 11 on contactor. Place the wiring diagram provided with the kit on the inside of the control box cover. Cut quickconnect off other crankcase heater wire strip and connect to stripped temperature switch wire with a wire nut. The approved oil is a polyolester poe lubricant emkarate rl68hb. Ae4 1388 r3 20 to 40 ton zpkc and zrkc copeland scroll air conditioning compressors ae4 1388 r3 june 2014 safety. Reapply power to the unit.

2014 emerson climate technologies inc. Due to the copeland scrolls inherent ability to handle liquid refrigerant in flooded conditions a crankcase heater is not required when the system charge does not exceed the charge limits shown in table 4. Reinstall the side panel and the unit top and the control box cover. Of course it would be even better if it was wired through auxiliary side contacts and shutoff when compressor energizes. Cad drawing diagrams. Cut quick connect off other crankcase heater wire strip and connect to stripped temperature switch wire with a wire nut.