To further increase longevity arb compressors are also rebuildable. Page 15 air locker solenoids to an arb air compressor all connections can easily be set up using only the supplied wiring loom arb 180409 shown in figure 7 consulting the wiring diagram fig7 for wire colors and the switch terminal illustration fig8 plug each of the female spade terminals onto their appropriate switch terminal.

On Board Air Compressors

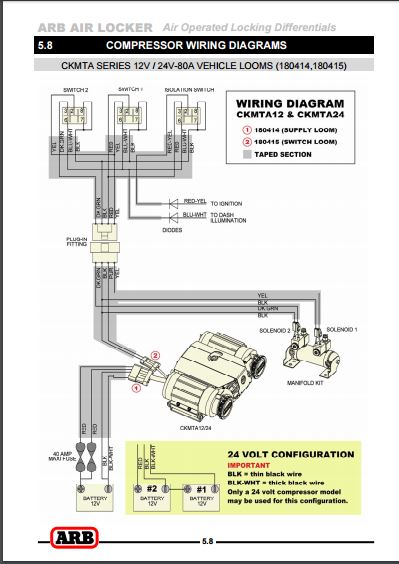

Arb compressor wiring diagram. Take to the air supply in a snorkel or other part of the air ducting for engine aspiration however if an extension tube is used to relocate the compressor intake to the engine intake supply then it must be understood that the negative. Remove one of the 1 8 bspt plugs from its port in the compressor manifold using a 5mm hex key. Arb air locker activation system. To download or view any of the service and parts manual section pdfs simply expand the section youre interested in by clicking on the red plus icon then click on the section number in the left hand column next to the item description. Arb air locker air operated locking differentials 58 58 compressor wiring diagrams ckma series 12v 24v 40a vehicle loom 180409 switch terminal identification up. Designed specifically for air locker activation and sealed for moisture and dust resistance this compact on board compressor comes with a full wiring loom for simplified installation and plug in connectivity to air locker control solenoids.

Service and parts manual. Arb does not recommend connecting the compressor in. For total peace of mind all arb compressors come with a comprehensive 2 year warranty. Arb air locker air operated locking differentials 58 58 compressor wiring diagrams ckmta series 12v 24v 80a vehicle looms 180414180415. This step applies to the 12v solenoid that is packed with each arb air locker differential. Of air pressure will work in place of the arb pump.

If the compressor is to be used for an alternate purpose then simply skip this step and plug or terminate the ports as required by the application. Designed to withstand the harshest environments each arb air compressor is individually leak tested current draw tested and flow tested under heavy load at the factory before packing. Any good pump that supplies 95 to 115 lbs. If the customer purchases both the arb pump and the arb differential all of the parts needed are included even the wiring. Unit can not be engaged while a wheel or wheels are slipping.