40 low starting current balanced magnetic field. Schematic wiring diagrams see chapter schematic wir ing diagrams page 9.

Clearance Volume An Overview Sciencedirect Topics

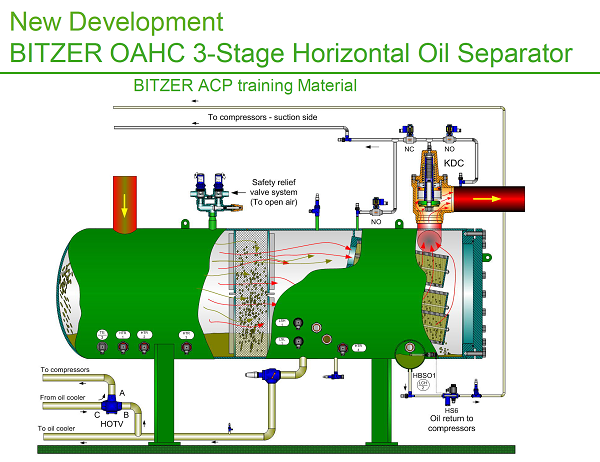

Bitzer screw compressor wiring diagram. The module switches the oil heating on and off and depending on the equipment of the compressor the start unloading the compressor cool. Bitzer will not be responsible for system engineering or re engineering. For replacement compressor selection a capacity comparison of each compressor is given in table 1 and dimension information is given in table 2. Special features of the bitzer motors many years of experience with part. Bitzer applications engineering is available for review of the final compressor selection and to provide recommendations as necessary. Horizontal screw compressor to a fusheng bsr compressor.

8 cylinder compressors 60. Ers of the reciprocating compressor. The engine and discharge gas temperature oil supply and application limits. Pgd1 user terminal for panel installation 8 rows by 20 columns pgd1000f00 4. Driver for bitzer csh screw compressors software flstmbsde 2. The terminals m1 m2 or t1 t2 on the com pressor and 1 2 on the protection device must not come into contact with the control voltage or.

The suction and discharge connection sizes are different between the bitzer cs and fusheng bsr compressors. This includes final compressor selection condenser sizing refrigeration line sizing oil system electrical wiring or components. Size information is given in table 2. 31 schematic wiring diagram and motor connection 3 raccordement électrique 31 schéma de fonctionnement et. Notice potential failure of the compressor protection device and the motor due to improper connec tion andor faulty operation. Pco5 medium with built in eev driver for bitzer csh screw compressors software installed kit pco5bz010k in addition the following are available to complete the system.

Cs screw compressor troubleshooting guidelines 01 april bitzer compressor wiring diagram sometimes a photo can support engineers troubleshoot your design. It protects the compressor from operating under critical conditions. Especially if quality issues are suspected such as soldering reliability unsuitable connections wrong polarities and further problems which might be revealed in a photo.